Release of Sonex/Waiex/Xenos A and B Model Rotax Installation Kits

As we begin releasing these kits, they are made to order. Realizing each aircraft builder does things a little bit different than the last, we can help, or direct you in the easiest and most effective direction to help you with your project.

Our basic cooling system assembly and scoop are priced at $1,350.

Our complete kit; which is our cooling system assembly, scoop, oil thermostat, all fittings required, all hoses requires, all clamps required, oil can bracket, oil catch can, coolant reservoir, heat soak vents, and hardware, is priced at $1,950.

Propeller, spinner, throttle system, and more miscellaneous items are available to complete your installation.

These assemblies (and additional optional components) are compatible with Sonex, Waiex, and Xenos, both A and B models. It requires the use of Sonex Aircraft's engine mount and attach bars, cowling side vents (And yes, the A model uses them too), Toucan exhaust system specially designed for Sonex, and Sonex's Rotax propeller spacer.

We HIGHLY recommend a horizontal split cowling and do not support the use of a vertical split cowling. From there the components are mount, plug, play.

Please contact us with the form at the bottom of the page, through our store, or feel free to give us a call.

We purchased our Sonex in May 2020 with the intention of installing a Rotax 912 series engine after noticing Sonex Aircraft had made a Rotax engine mount for their aircraft (They had been making them for a few years). With no models or instructions to base our installation off of (none in the U.S. and very few in other parts of the world), we initially had to shoot from the hip to install the engine. We installed a used Rotax in our Sonex. Used engines are readily available on the market, and even with over 1,000 hours, Rotax's will run 1,000 more without batting an eye.

Admittedly, the first install was not very pretty, but it was very functional. Initially we wanted to see if a Rotax powered Sonex was even a good fit, being that Sonex had already produced their aircraft with their AeroConversion's AeroVee (80hp) and AeroVee turbo (100hp), and the Jabiru 2200 (80hp) and Jabiru 3300 (120hp). After 7 months of hard work, our Rotax powered Sonex was ready for flight. In the beginning we had to overcome some hurdles with the initial engine mount design. After the release of a second generation attach-bar system (which had proven to be very successful) we were able to begin racking up hours in the Sonex. After flying off our Sonex's phase 1, we were able to fly to Airventure in 2021. We had a very exciting 3,500 mile round trip from Arizona to Wisconsin.

Being the only flying Rotax powered Sonex in the U.S., our Sonex was the "Ugly Duckling" of the fleet. Since it had been proven to be (arguably) the best performing Sonex configuration, we realized it needed a presentable face lift. We then got to work reimagining the image of a Sonex.

Sonex's are always seen with a fixed pitch, 2 blade propeller. Whether it was a Sensenich, Prince, etc, the norm was usually of one of those propellers and a small billet aluminum spinner/squash-plate. John Monnett, creator of Sonex Aircraft (and many more aircraft before that), had run with a timeless design variation that he had made decades before. While this was very attractive and Sonex's signature look, we wanted to do something a little different.

Our previous Jabiru 3300 equipped Sonex Legacy tri-gear.

In its first configuration, we had used the vertical split cowling. This cowling does not lend itself well to the Rotax because it has all its components on top of the engine for the most part, and carburetors on either side (depending on the model). So we purchased a horizontal split cowling from Sonex.

The only look that stayed was our 64", tapered tip, HPL 3 bladed propeller from Warp Drive. Warp Drive produces the strongest propellers in the light aircraft world, and one of the best performing propellers. Operating off of dirt and gravel (our Sonex does not live on pavement), Warp Drive was a no brainer. We fitted it up with a 9.75" carbon fiber spinner and the new cowling. We had to redesign our cooling system and exhaust so it wasn't hanging out in the open. Getting creative with some cooling designs that had been proven in the P-51 Mustang and Indy Car/F1 racing world, we created a cheap and effective way to keep the engine happy in all aspects of flight and in varying climates. After some math and theory, we began forming foam, fiberglass, a few reshaped pieces here and there, some intersection fairings, threw on some paint, and we had a modernized and fresh look for the Sonex.

Since then, Sonex chipped away at employee Cris Nash's Rotax 912 iS powered Sonex B, and Airventure hosted another successful One Week Wonder in 2022 featuring a Waiex B with a Rotax 912 iS. We were extremely fortunate to be asked to participate in this build, and be a small part of an incredible feat. Having been touched by thousands of hands and hundreds of man hours in just a week's time, the OWW was a testament that anything is possible when you get thousands of people together sharing such passion. My hat is off to the EAA and Sonex Aircraft especially. Everyone at Sonex (Mark, Cris, AJ, Tony, Tom, Steve, Nathan, Kerry, John, and pardon me if I forgot more people) worked tirelessly, with basically no sleep for a week, to make sure the Waiex made its way to show center for the everyone to see and experience. I cannot believe how hard they pushed themselves and it was an opportunity I will never forget.

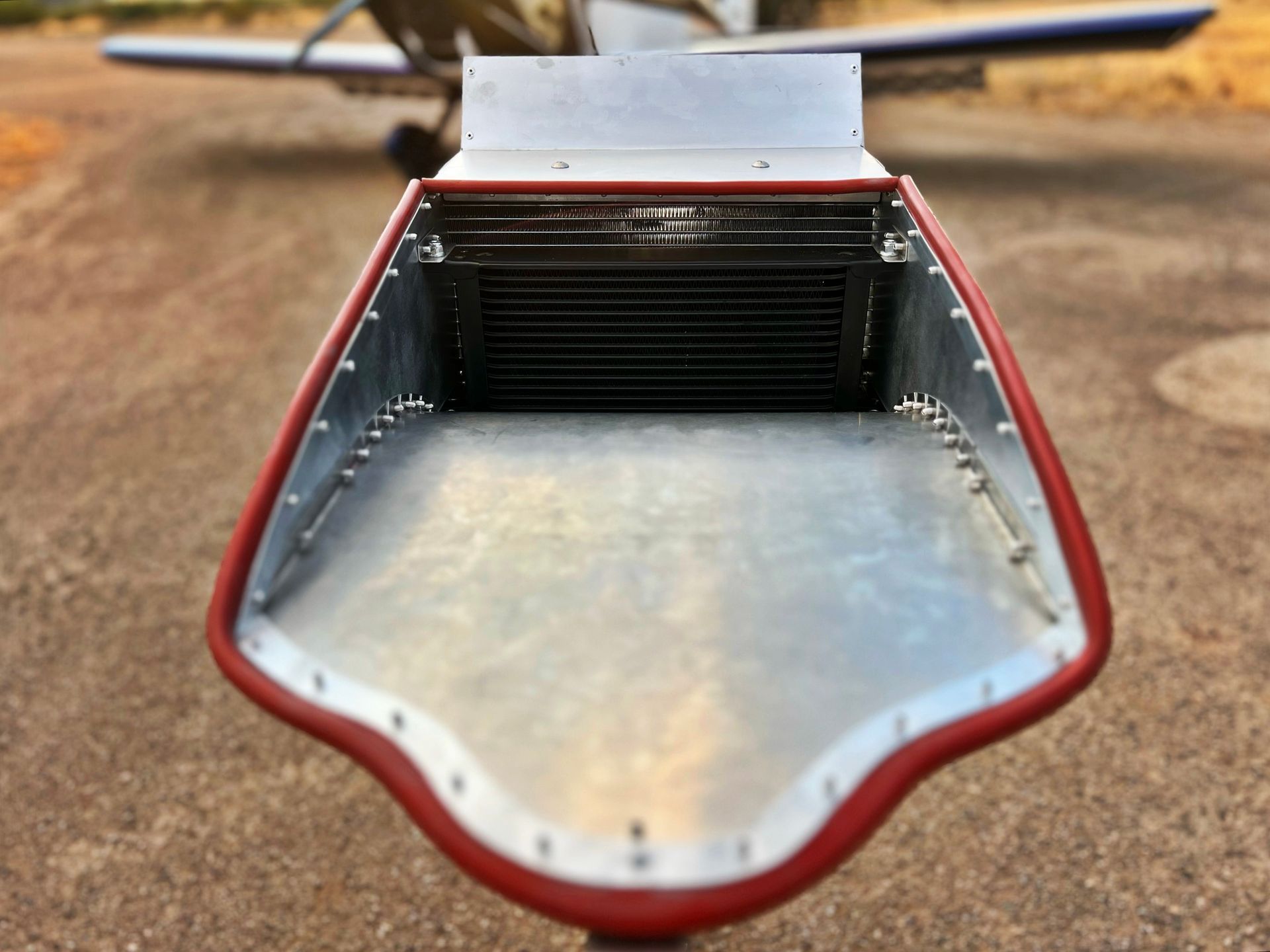

Now that there's two flying Rotax powered Sonex's in the U.S. (EAA's and ours) and a third on the way (Cris's from Sonex) it was apparent the pairing was going to grow among the community. Having flown our Sonex to Airventure three times (2021, 2022, 2023) the proof of concept was there. After some pressure from a few folks, especially Bryan Walstrom (Experimental Aircraft Channel, thanks buddy) and a wonderful meeting with Sonex Aircraft, we began flight testing in 2024 to produce a simple firewall forward option for those wanting to install a Rotax 912 series engine in their Sonex. Essentially a basic copy of our current configuration with minimal changes/improvements, our package is very simple to install. The basic kit includes a cooling package the bolts up to the bottom of the engine mount to be fitted to the cowling and a scoop to be blistered in. The cooling "Scoop Assembly" seals to the bottom of the cowling from pressure and 1 screw. From there we offer everything needed to work in conjunction with Sonex Aircraft's supplied parts. Fittings hoses and clamps, oil can bracket, oil catch can, coolant reservoir, propeller, spinner, throttle system, and more miscellaneous items are available to complete your installation.

With different Rotax platforms available (914, 915, and 916) future installations of these engines are something we're looking into. While 100hp does the Sonex magnificently, we realize folks always want more. The current parts available only support the 912 series engines. Rotax produces the 912UL, 912ULS, 912iS, 914UL, 915iS and 916iS, ranging from 80hp-160hp with very minimal weight from model to model (125-190 pounds), burning 3.5-7 gallons an hour and 2,000 hour TBO's. It's a no brainer why people choose Rotax. While new Rotax engines are not cheap (cheap ain't good, good ain't cheap), the used market is a great outlet for engines that have plenty of life in them at a much lower cost. As previously mentioned, our Rotax is a used, nearly a 20 year old engine, and that doesn't bother us one bit.

We're looking forward to growing and working with the Sonex community. See you guys in the sky!